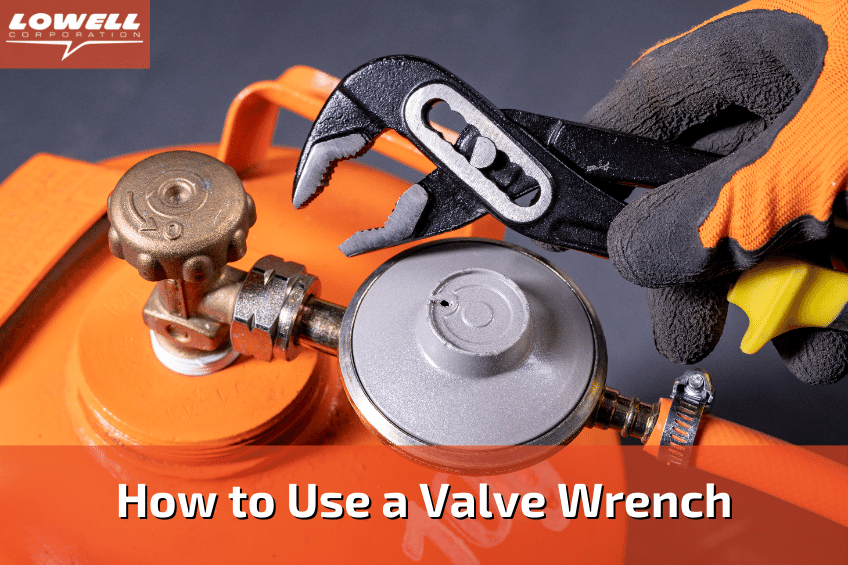

How to Use a Valve Wrench

A valve wrench is a versatile tool for various household or industrial applications. It is one of the most common pipeline tools in a toolset. Read this article to learn how to use a valve wrench for various valves.

What We’ll Cover:

- What is a valve wrench?

- Types of valves

- Common applications of valve wrenches

- Steps to using a valve wrench

- Key takeaways

What Is a Valve Wrench?

Valve wrenches are indispensable tools that help you to tighten and loosen nuts, bolts, and valves. Valve wrenches have a hooked head to provide a powerful and non-slip grip to prevent the wrench from slipping when turning valves. They provide a mechanical advantage when working on fasteners.

Wrenches come in different sizes and shapes. The type of valve wrench you need will depend on the valve or rotary fastener you use.

Types of Valves

Valves are mechanical devices attached to pipes that regulate, control, or deal with a fluid flow, such as water, air, and oil pipelines. There are several different kinds of valves available for pneumatic and hydraulic functions. Some of the types of valves are:

Air Logic Valves

The air logic valve is also called the shuttle valve. Shuttle valves automatically open and close in response to the functional parameters of the valve. Air logic valves inject a degree of logic into a regulating system. The aerospace industry, automobiles, and mining applications are the most prominent users of air logic valves.

Balancing Valves

Balancing valves are for regulating and measuring the flow of fluids equally into numerous branches.

Cartridge Valves

Also known as 2/2-way valves, cartridge valves regulate the direction and flow of pneumatic fluid power systems. They are hugely popular, and you can use them for different purposes.

Christmas Tree Valves

Just as the name implies, Christmas tree valves look like Christmas trees. They are a system of valves with many parts used to control products from a well. These valves mostly appear in offshore oil rigs.

Cock Valves

In plumbing, cock valves, also referred to as quarter-turn valves or plug valves, is a valve that drains tanks. It permits or restricts the flow of liquid or gas through a gas. They are often used in manufacturing plants, other industries, and residential settings.

Float Valves

The float valve is also called the ball-cock. It is a simple way to control the liquid level in a tank. It opens or closes a valve depending on when a float senses that the level of the liquid has risen or fallen.

Hydraulic Valves

Hydraulic valves are a fluid power control type that regulates the flow and pressure of fluids in a hydraulic circuit.

Needle Valves

Needle valves are ideal for any situation where you must regulate fluid flow and pressure with fine precision. This valve includes a plunger shaped like a needle. Hence, it is sometimes called a plunger valve.

Poppet Valves

A poppet valve is also known as a mushroom valve. It is a device that regulates the flow of gases to pneumatic cylinders.

Solenoid Valves

A solenoid valve is an electromechanical device that controls the flow of a fluid or oil by opening and closing a control unit. The control unit is either shut off or on. When it is on, the fluid flows through the valve.

Looking for high-quality pipeline tools? Read our product guide for pipeline workers.

Innovations in Wrench Design for Pipeline Engineers

Over the years, wrench technology has come a long way, offering pipeline and waterworks engineers tools that are more efficient, durable, and precise. Today’s tools are built to handle the evolving challenges of the job while minimizing effort and maximizing safety. From advanced materials to ergonomic designs, these innovations are shaping the future of wrench technology and making essential tools like valve wrenches indispensable on job sites.

The Rise of Ratcheting Mechanisms

One significant advancement is the integration of ratchet mechanisms in tools like the strap wrench and socket wrench. These features allow for smoother operation and better control, especially when working in tight or hard-to-reach spaces. A ratchet strap wrench, for instance, combines the gripping power of a strap wrench with the added convenience of a ratcheting motion, making it ideal for pipeline engineers dealing with slick or irregular surfaces.

Lightweight and Durable Materials

Another key innovation is the use of lightweight yet durable materials like high-strength steel and composite polymers. These materials ensure tools can withstand heavy-duty use without adding unnecessary weight to a technician’s toolkit. A well-designed socket set, for example, balances strength with portability, making it easier for engineers to carry and use in demanding conditions.

Ergonomic Designs for Comfort and Control

Ergonomic design has also revolutionized wrench usability. Handles with improved grip and comfort reduce strain during long hours of work. Valve wrenches, in particular, have benefited from these updates, allowing engineers to apply high levels of torque without sacrificing control or comfort. These ergonomic improvements are especially critical when paired with high-quality American-made tools, which prioritize durability and user experience.

Precision for Better Performance

Precision adjustments are another area where wrench design has advanced. Tools like the SureTork Pipeline Wrench now offer finely tuned torque settings, allowing engineers to apply the exact amount of force needed for specific jobs. This innovation not only protects equipment from over-tightening but also ensures pipelines and valves operate at optimal performance.

The American-Made Advantage

U.S.-based manufacturers like Lowell Corporation continue to lead the way with their commitment to crafting American-made tools. By producing wrenches and accessories that meet rigorous quality standards, they provide pipeline workers with the reliability they need to get the job done right. Whether it’s a valve wrench, a strap wrench, or a versatile socket set, these tools are built to last and designed with real-world challenges in mind.

Waterworks engineers need tough wrenches that can withstand heavy use.

Common Applications of Valve Wrenches

Waterworks engineers commonly use these tools for hydrant upkeep and repair. On the other hand, manual opening and closing valves are tasks often required in various industries, including automotive, oil, petrochemical, aerospace, power generation, and waste management. As a result, valve wrenches are also valuable in these fields.

Removing and Installing Valves

Use valve wrenches to take the valve off or install it. This method allows you to grip the valve’s handwheel easily and helps you open and close valves more efficiently.

Adjusting Pressure on Valves

Most waterworks tools have a metal knob that you can easily turn clockwise to increase or counterclockwise to decrease the pressure.

Valve wrenches loosen valves that are tightly shut, rusted, or stuck

Hard-to-open valves can be problematic. These wrenches offer a safe way to loosen firmly shut or stuck valves due to rust with little force. With valve wheel wrenches, you don’t have to pull the valve out with much force, which can damage it and make more work for you down the line.

They often provide the extra needed leverage to get that valve open again.

Enhancing Safety

If you are trying to stop a fire, there is no better fire service extinguisher tool than a valve wheel wrench.

Many types of fire protection equipment are available for homes, buildings, and other structures to help protect against fire threats. You can use a hydrant wrench to open a fire hydrant. It adjusts the water flow on the fire hydrant or tightens fire hoses.

Steps to Using a Valve Wrench

There are many different styles of valve wrenches available, but the steps for using them are pretty straightforward. Valve wrenches and hydrant wrenches have straightforward controls. You should be able to grab one and figure it out in the first minute or two.

The specifics on how to use the tools will vary from one type to another, but they work similarly.

- Start by using the hooked end to grab onto the wheel.

- To tighten the valve, turn the wrench in a clockwise manner. If you want to loosen it, turn it counterclockwise.

Make sure you exert only a little pressure to avoid damaging the valve.

Key Takeaways

There are a variety of wrenches that can come in handy around the house and across industries. Learning how to use these tools properly both saves time and proves useful for different projects.

Ready to save time and money on

your pipeline construction tools?

Making Pipeline Labor Easier Since 1869

Lowell Corporation offers the best hand tools in the industry. Whether you need a strap wrench or a socket wrench set, you’ll want the right balance between cost and efficiency. Our custom hand tools make tough jobs easier with pipeline and waterworks tools.

We’ve been increasing construction, maintenance, and manufacturing productivity since 1869. With our essential pipeline hand tools, you get the backing of the most trusted name in the hand tool industry.

Above all, Lowell Corporation is proud to manufacture all of its lineman tools right here in the U.S.A. in the heart of New England. All Lowell wrenches are 100% guaranteed with our one-year manufacturer warranty against defects in material and craft for one year from the delivery date.