What Is Highline Work?

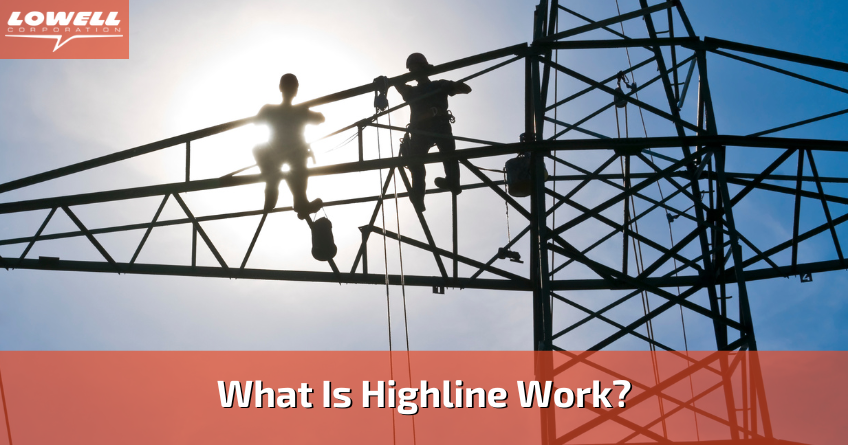

Ever marveled at the sight of linemen perched high above on power lines, maintaining the lifelines of our modern, electrified world? Highline work is an art that combines skill, precision, and courage. Every day, these dedicated professionals ensure that our homes, hospitals, and industries are powered and connected.

From the crackle of electricity to the buzz of data streaming across fiber-optic cables, linemen are the unsung heroes behind the scenes. Join us as we climb into the world of highline work, exploring the rigorous field training, essential equipment, and critical benefits these skilled workers bring to our communities.

Let’s discover what it takes for linemen to keep the American electrical grid working.

What We’ll Cover:

- What does highline work look like?

- Lineman wrenches

- Clamps

- Clusters

- Wire ferrules

- Scaffolds

- Hardhats

- Boots

- Insulated gloves

- Climbing belts

- Faraday cage suits

- How linemen repair power lines

- Key takeaways

What Does Highline Work Look Like?

Linemen are responsible for maintaining power transmission, distribution, and telecommunication lines. They ensure the end-users are facilitated by electricity and network supply in homes, offices, industries, and hospitals.

Moreover, they are also involved in fixing and maintaining the cable television lines and fiber optic lines. The process of highlines might also involve distributing transformers on poles, insulators, and fuses. They work on both live wires and dead wires.

The process involves physical exertion in inaccessible areas where you use manual tools. The process might involve ropes, knots, and lifting equipment. Linemen may use a pair of spikes and climb the wooden ladders or poles to gain access to the high wires. American wrench manufacturers provide some of the hand tools linemen use in the field.

However, linemen who must cover a considerable distance to high-tension power lines use helicopters. This process is complicated since it should be ensured that the linemen are isolated from the ground. The linemen also wear unique protective and conductive costumes while handling the wire.

What Tools and Equipment Should I Use for Highline Work?

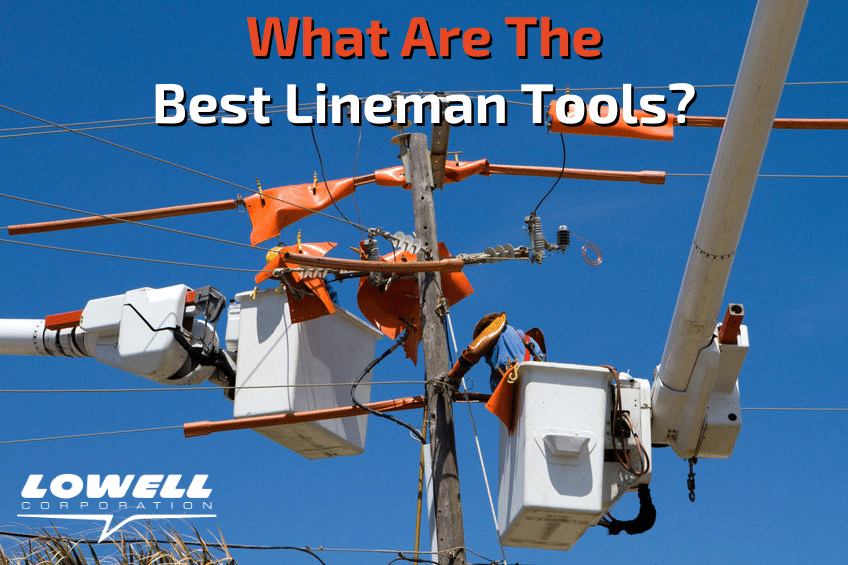

The linemen working on highlines need to service transmission and distribution lines. They might also have to work on live wires and rugged terrains.

Thus, they need many tools and equipment to handle their operation—these tools and equipment help them easily perform their tasks.

Keep reading to learn about some of the best lineman tools involved in highline work:

Lineman Wrenches

A lineman’s wrench is required for high-line pole installation and repair. American wrench manufacturers develop specialized, tight ratcheting mechanisms for these purposes. The long handle of the wrenches also ensures greater leverage. Some socket wrenches come with bolt-through designs that enable use on long bolts. It also provides you with a smooth surface for hammering.

Linemen or “spud wrenches” are essential tools for utility workers who perform maintenance and repair on power lines, transmission towers, and other electrical infrastructure. These wrenches are designed to fit over the bolts and nuts that secure heavy-duty electrical components in place, allowing workers to tighten or loosen them as needed quickly.

With their adjustable jaws, these wrenches can tackle a wide range of bolt sizes and configurations, making them a go-to tool for utility workers who never know what kind of hardware they need on any given job. The durable, heavy-duty construction of these wrenches also ensures they can withstand the harsh conditions and heavy loads that utility workers encounter daily.

Clamps

Wire clamps, also known as cable grips or wire grips, are essential tools for utility workers who work with electrical cables and wires. These clamps are designed to securely grip the cable or wire, preventing it from slipping or moving during installation or maintenance. They are typically made from high-strength materials such as steel or aluminum and are available in various sizes to accommodate different cable or wire diameters.

One of the key benefits of wire clamps is that they help to improve electrical safety for utility workers. When working with live electrical cables or wires, it’s essential to ensure they are securely anchored to prevent the risk of electrical shock or other hazards. Wire clamps provide a secure anchor point, reducing the risk of the cable or wire coming loose and causing an accident.

Wire clamps can also help to improve efficiency and productivity for utility workers. By securely holding the cable or wire in place, workers can perform their tasks more quickly and accurately without worrying about the cable or wire moving or shifting during installation or maintenance. This grounding can help to reduce the time and effort required for each task, allowing workers to complete more work in less time and with greater confidence and safety.

Clusters

Clusters, also known as four-way connectors, are essential tools for utility workers who need to splice or connect multiple cables or wires. These connectors typically consist of a central body with four or more arms, each of which can be connected to a separate cable or wire. They are available in various sizes and materials to accommodate different cable or wire diameters and types.

In electrical work, clusters provide a secure and reliable method for splicing or connecting multiple cables or wires. By securely connecting each cable or wire to the central body of the cluster, workers can create a strong and stable connection that is less likely to come loose or fail over time. This instability can be especially important in applications where the cables or wires are exposed to environmental stressors, such as vibration or extreme temperatures.

Another benefit of clusters is that they help simplify the process of splicing or connecting multiple cables or wires. Instead of splicing or connecting each cable or wire individually, workers can use a single cluster to connect multiple cables or wires at once. This step can help to save time and effort and can also help to reduce the risk of errors or mistakes during the splicing or connection process.

Wire Ferrules

Wire ferrules, also known as cord end terminals or wire end sleeves, are small metal or plastic sleeves crimped onto a wire’s end. They provide a neat and secure connection between the wire, terminal block, or another connection point. Wire ferrules are available in various sizes and materials to be compatible with various types of wire.

Wire ferrules help linemen improve the reliability and safety of electrical connections. By providing a secure and stable connection between the wire and the terminal block or other connection points, wire ferrules help to prevent the wire from becoming loose or disconnected over time. This precaution can be especially important in applications where vibration or other environmental factors may cause wires to become loose or disconnected.

Overall, wire ferrules can help to simplify the process of making electrical connections. By crimping a ferrule onto the end of a wire, workers can create a neat and uniform connection that is easy to insert into a terminal block or other connection points.

Scaffolds

Scaffolds are temporary structures that provide a stable and secure platform for workers to perform their jobs at heights. They are typically made from metal or wood and designed to be easily assembled and disassembled. Scaffolds come in various sizes and configurations to accommodate different types of work and can be customized to fit specific job requirements.

Furthermore, scaffolds are that they provide a safe and stable platform for workers to perform their jobs at heights. This footing is especially important for utility workers who perform maintenance or installation tasks on poles, towers, or other elevated structures. Scaffolds provide a secure and stable working platform that allows workers to focus on their tasks without worrying about safety.

The best application of scaffolds is that they can be easily moved or repositioned. This application can be especially important in applications where workers must move from one location to another, such as when installing or repairing power lines or communication cables. Scaffolds can be quickly and easily disassembled and moved to a new location, providing workers with a stable and secure platform to work from.

Linemen need tough wrenches that can withstand the test of time. Trust Lowell to make your repairs easier.

Lineman Safety Equipment

Lineman safety equipment ensures that the linemen, while working on high-tension wires, stay protected from electric shocks. The safety equipment includes wearable items along with other equipment to support an array of lineman wrenches.

Hard Hats

Hard hats are essential to the linemen’s gear since they can prevent head injuries during a fall and serve as protection. Face shields are often attached to these hats to stay protected from flashes.

Boots

Rubber boots protect against electric shocks, especially when working on metallic poles.

Insulated Gloves

Linemen working on highlines and live wires also require insulated rubber or leather gloves. These gloves offer assistance while handling live cables and fixing them.

Climbing Belts

Climbing belts offer help while climbing utility poles. These belts also prevent falls and accidents. They also support the weight of the linemen.

Faraday Cage Suits

While working on high-tension wires, some electric linemen might also use Faraday cage suits. These suits work on live, high-voltage power lines. The design of this cage suit also mitigated the risks of electrocution and shocks. It prevents the flow of current in your body.

How Linemen Repair Power Lines

One of the essential parts of the job of a power lineman worker is to repair high-voltage lines. Due to climatic or extreme cases, unprecedented wire and transmission line damage often needs urgent repair after storms and other adverse weather.

Highline workers urgently need to respond to calls about damaged power lines. They have to lift heavy equipment and work for long hours, making repairs. Often, there is a hindrance in the cables or power lines.

The repairing process involves climbing poles and transmission towers. It also involves scrutinizing defective devices, worn-out wires, transformers, and switches. During the procedure, the equipment supplies truck-mounted buckets. The process also requires testing power lines until repairs are complete. It may require operating the power equipment while installing and repairing poles, towers, and transmission lines. Power linemen may replace the old, worn-out wires with newer ones and fix the blown-out transformers.

The repairing process relies heavily on problem-solving, organization, and management skills. It also requires strategic and efficient planning. Linemen often need to find quick solutions to fix the situation to save the electricity supply.

Key Takeaways

Working on a highline is one of the most arduous and laborious jobs. The duties of the linemen workers are demanding in various ways. The workers need to be efficient while handling and responding to emergencies. They must learn and practice using highline and powerline tools effectively at the right time. Another important aspect of this career is securing the right American-made tools for repairing and maintaining American utilities.

Overall, linemen’s wrenches play an essential role in helping utility workers maintain the integrity and safety of our electrical infrastructure. Whether replacing a broken insulator on a transmission tower or tightening bolts on a substation transformer, these wrenches are a must-have tool for any worker who wants to do the job quickly and safely.

Ready to save time and money on

your lineman tools?

The Best American Wrench Manufacturer Since 1869

Lowell Corporation offers the best industrial tools in the industry. Whether you need a crank handle or a valve wrench, your company deserves the right balance between cost and efficiency. Our custom hand tools make tough jobs easier for design engineers, waterworks engineers, and utility linemen. We’re proud to distribute lineman tools with J.L. Matthews to help linemen nationwide.

We’ve been increasing construction, maintenance, and manufacturing productivity since 1869. Let our trusted socket wrench innovations simplify your workload, no matter which strap wrench set you need. With our essential industrial OEM tools, you get the backing of the most trusted name in the hand tool industry.

Lowell Corporation is proud to manufacture all of our lineman tools in the U.S.A. in the heart of New England. All Lowell wrenches are 100% guaranteed with our one-year manufacturer’s warranty against defects in material and craft for one year from delivery.

Make sure to follow us on Instagram for exciting product updates and promotions!